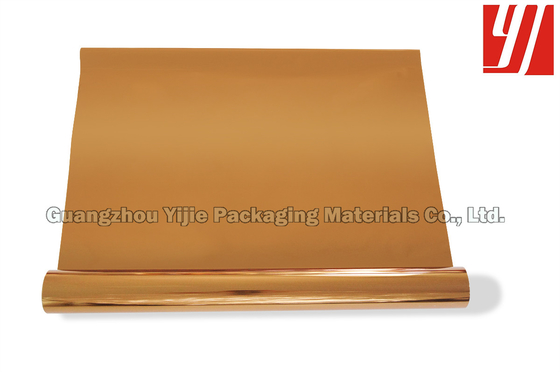

Copper Hot Stamping Foil For Paper Plastic Textile Leather PP PE PVC Labels OPP Laminates

Company Profile

Guangzhou Yijie Packaging Materials Company Limited is a high-tech enterprise integrating research and development, production and sales of hot stamping foil, PET film, BOPP film, PVC film, laser film, scratch resistant film, soft touch film and other special films.Our hot stamping foil brand "Yijie" is widely used in high-end cigarette case, wine boxes, cosmetic boxes, books, greeting cards, leather products, wood products, fabrics items and other printing and packaging fields. With 20 years experience in the stamping foil industry, Yijie is a name you can rely upon to deliver fantastic graphic printing results.Our hot stamping foils can be applied to a wide range of substrates and surfaces. At YIJIE foils, our goal is to make your brand shine by manufacturing the best performing foils, films and foil laminates in the graphics industry. We accomplish this through extensive research, development and testing to ensure our foil and film products perform without equal on your finished product.With a wide array of brilliant silver, gold and colors as well as eye-catching stocks and custom holographic foil patterns, YIJIE Foils is also a key partner when it comes to the critical custom color matching required by certain brands.

About Hot stamping foil

Hot stamping foil is one of the methods of transferring foils to a surface at a hot temperature. We have developed a wide range of hot stamping foils for nearly every single type of application. Within the industry, each type of application is assigned a reference known as a grade. Hot foil grades are determined by the type and quantity of adhesive that is used with foil.

Quick Details

- Material:

-

PET

- Type:

-

Metallized Film

- Usage:

-

Packaging Film, Bookbinding,Packaging,Food Packaging

- Place of Origin:

-

China

- Brand Name:

-

Yijie Brand

- Model Number:

-

Other colour-03

- Product Name:

-

Hot Stamping Foil

- Color:

-

Kinds Of Design

- Thickness:

-

12 Micron

- Length:

-

120m-8000m

- Width:

-

0.64m-1.5m

Markets

· Bath & Body

· Corporate Identity

· Cosmetics

· Entertainment Media

· Fine Food and Beverage

· Fashion

· Greetings

· Personal Care

· Publishing

· Stationery

· Wine

· Spirits

Tyical Uses

· Bags

· Book Wraps

· Clear Labels

· Folders

· Folding Cartons

· Games/Media Covers

· Greeting Cards

· Hang Tags

· Media Wraps

· Presentation Folders

· Print Collateral

· PS Labels

· Rigid Packaging

· Set-up Boxes

· Stickers

· Tobacco Cartons

· Wine Labels

Features

- Wide range of colors

- Reflective Surface

- Holographic Patterns

- Custom Patterns

- Transparent Patterns

- Clear Foils

- Silk + Gloss Finishes

- Recyclable

Product image

Usage and precautions

1.Selecting appropriate foil according to different types of stamping. During hot stamping, you must master the three-way cooperation of temperature, pressure and hot stamping speed for proper adjustment. Hot stamping materials and hot stamping area are also considered.

2.There is a vacuum aluminum plating layer on the hot stamping foil which is very sensitive to acid, alkali and humid environment. Therefore, the paper, ink (especially black), dry oil and compound glue must be neutral. At the same time, the material for hot stamping must be kept dry to avoid oxidation or damage of the bronzing layer.

Production Procedure

Certificate

Q/A

What is hot stamping foil made of?

polyester film

The foil web is not actually “punched out” in the die contact areas, rather, specific layers are activated by the heat and pressure to adhere to the part and release from the web material that the foil is made on which is usually polyester film.

What is hot stamping process?

Hot stamping is a lithography printing process that uses heated image molds or stamping dies to transfer metal foils or pre-dried inks onto a surface. Hot stamping foils have three layers: a color layer (which can be pigment or metallic), an adherence base, and a release layer.

What is a hot foil stamping machine?

In a hot stamping machine, a die is mounted and heated, with the product to be stamped placed beneath it. A metallized or painted roll-leaf carrier is inserted between the two, and the die presses down through it. The dry paint or foil used is impressed into the surface of the product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!